Enhanced Durability for Use in Extremely Harsh Environments

Reliability Equal to Sn/Ag/Bi/Sb/Ni/Cu Alloys with Wider Assembly Process Window

Mitigates Tin Whisker Formation

Creep Rates Lower Than SAC Alloys

High Reliability / High Strength

Improved Thermal Cycling Performance

Improved Wetting Versus All Low/No-Silver Alloys

For use in Lead-Free Process Only

DEscriptION

AIM’s REL22 alloy is comprised of tin, bismuth, silver, copper, antimony, nickel and trace amounts of elemental grain structure refiners. The alloy provides significantly improved durability for use in applications where thermal shock, vibration and high g-forces are a concern. REL22 is the solution when SAC alloys are incapable of surviving in harsh environments, such as automotive, aerospace and geographical exploration equipment.

AVAILABILITY

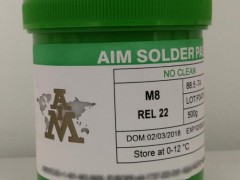

REL22 is available in bar (1.1 kg / 2.5 lb), solid feeder wire (diameters of 3.175 mm /.125”), and no clean solder paste (M8 T4 500 gr jar). Other product options are available upon special request.

HANDLING & STORAGE

Solid wire and bar solder products have an indefinite shelf life when proper storage conditions are observed. See solder paste TDS for shelf life information. Consult the SDS for specific handling procedures.

SAFETY

Use with adequate ventilation and proper personal protective equipment. Refer to the accompanying Safety Data Sheet for any specific emergency information. Do not dispose of any hazardous materials in non-approved containers.

通过认证

通过认证